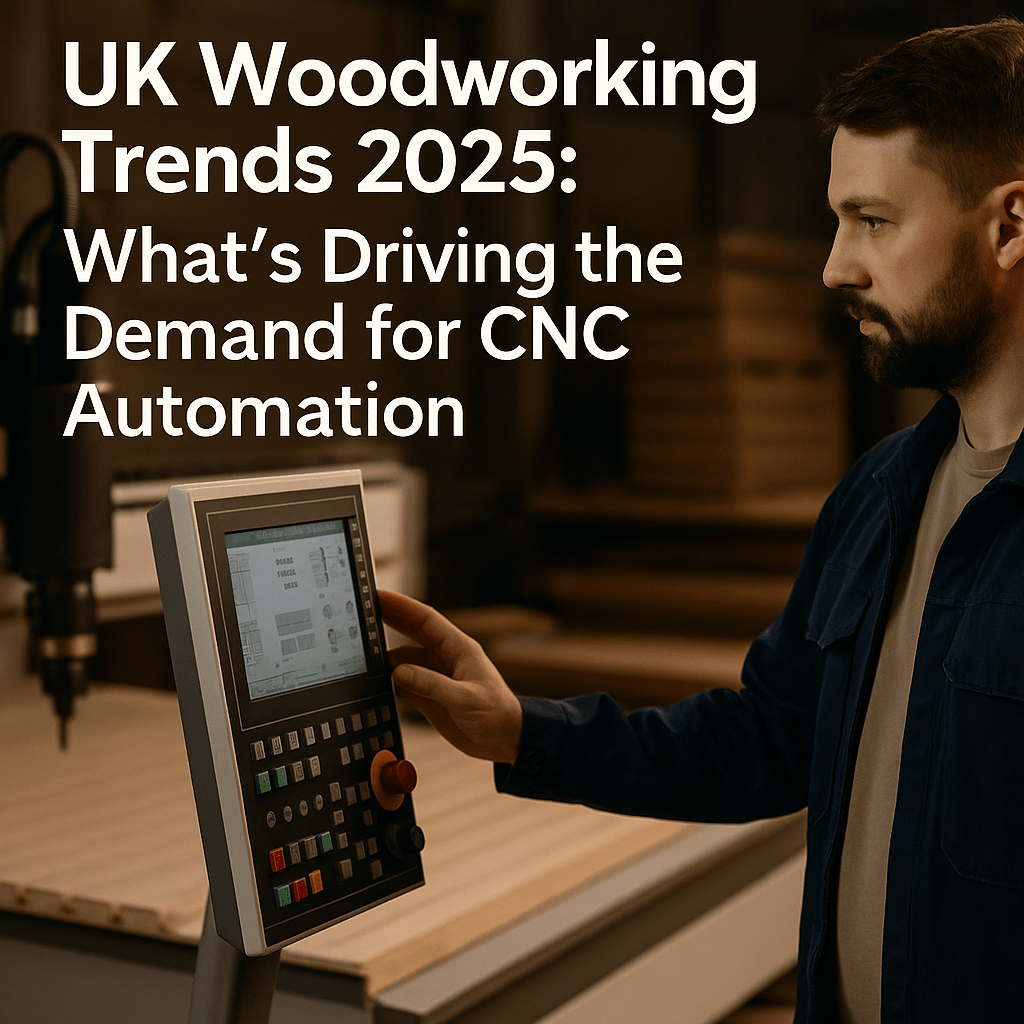

As the UK woodworking industry continues to evolve, 2025 is shaping up to be a landmark year for CNC (Computer Numerical Control) automation. From joinery workshops to bespoke furniture makers, small and medium-sized businesses across the UK are embracing CNC technology to boost efficiency, quality, and competitiveness.

In this article, we explore the top CNC woodworking trends in the UK, the rise of automation in joinery, and what’s driving more workshops to invest in CNC systems. Whether you’re new to CNC or planning your next machinery purchase, this guide is packed with insights.

Current CNC Woodworking Trends in the UK

The demand for precision, speed, and customisation is pushing UK woodworkers to rethink traditional processes. Here are the standout trends for 2025:

- Smaller CNC Machines for Small Workshops: Compact and affordable CNC routers are becoming more popular among small CNC businesses and start-ups.

- Hybrid Workflow Integration: Workshops are blending manual craftsmanship with digital automation to retain a bespoke touch while scaling production.

- Eco-Friendly Production: Sustainability is influencing design and production decisions, and CNC machinery helps reduce waste and material usage.

CNC woodworking trends in the UK show a clear shift toward smarter, leaner operations with an emphasis on quality and repeatability.

The Rise of Automation in Joinery & Furniture Manufacturing

Automation in joinery isn’t just for large factories anymore. Thanks to user-friendly software and more accessible machinery, even small workshops can automate key processes like:

- Cabinet cutting and nesting

- Precision drilling and routing

- Edge banding

By automating repetitive and labour-intensive tasks, businesses are:

- Reducing lead times

- Improving accuracy

- Freeing up skilled workers for creative and finishing tasks

Automation in joinery is becoming a competitive necessity for UK-based manufacturers.

Why Small and Medium-Sized Workshops Are Investing in CNC

The myth that CNC is only for big-budget operations is quickly fading. Today, small CNC businesses are seeing strong returns by investing in CNC systems. Why?

- Affordability: Entry-level machines are now within reach for most SME budgets.

- Labour Shortages: With skilled workers in short supply, automation helps maintain output.

- Customisation Demands: CNC machines enable bespoke design at speed and scale.

For many, buying CNC technology is not a luxury—it’s a strategic move to future-proof their operations.

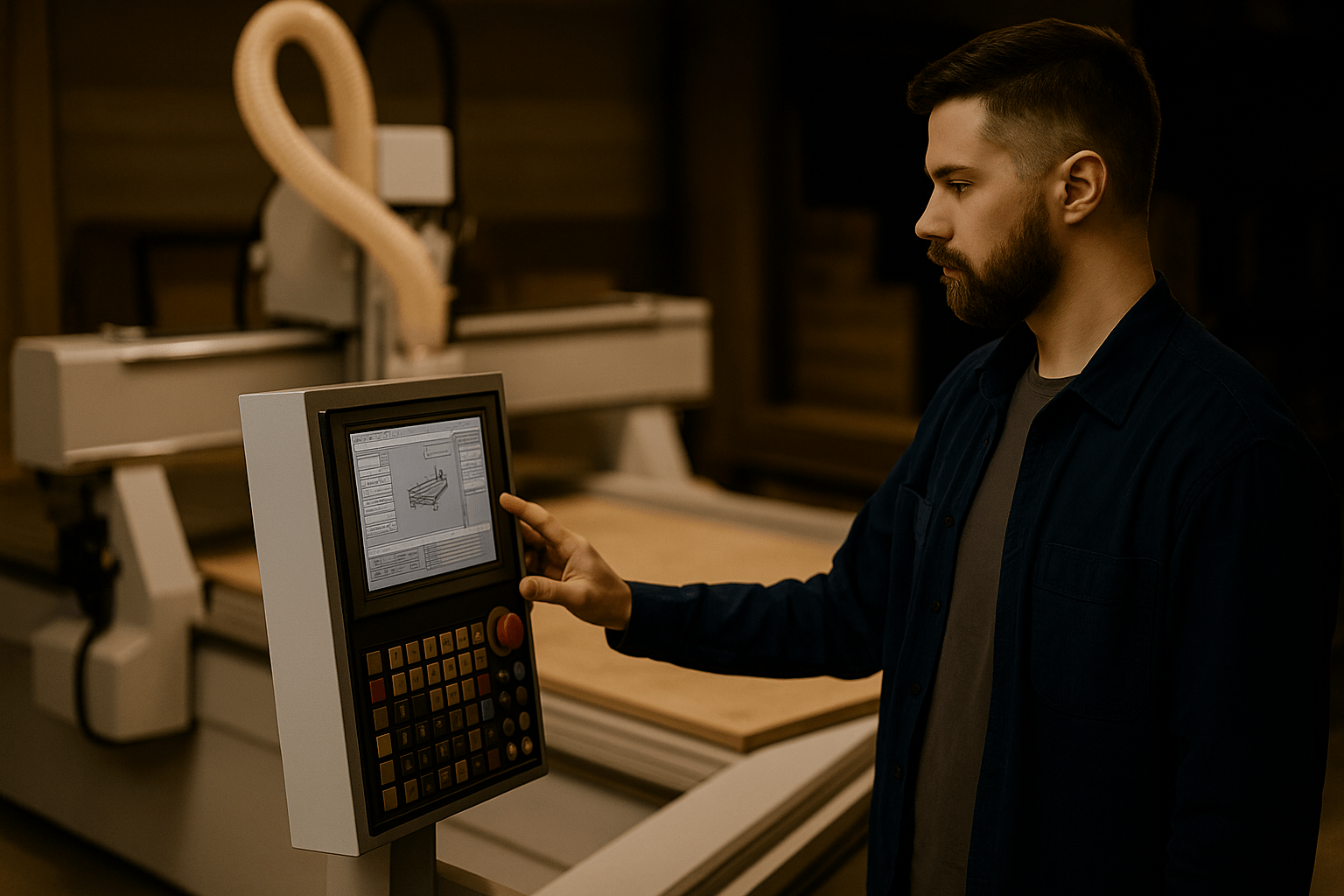

Buying CNC: Delivery and Setup Process in the UK

When it comes to buying CNC machinery, understanding the delivery and setup process is crucial—especially for beginner CNC users.

Here’s a basic breakdown of what to expect:

1. Initial Consultation

Discuss your production goals, space, and materials with a supplier to choose the right system.

2. CNC Machine Delivery UK

Many suppliers, including Micromax Group UK, offer CNC machine delivery across the UK, complete with risk-free transportation and handling.

3. Machinery Setup Process

Professional engineers will handle installation, testing, and fine-tuning. For those following a beginner CNC guide, expect basic training on safety, operation, and maintenance.

Smooth delivery and setup ensures you’re up and running fast—with minimal downtime.

The Future of CNC Technology in the UK Market

The CNC future in the UK looks promising, with innovations aimed at increasing productivity while reducing the learning curve:

- AI-Driven Optimisation: CNC systems with artificial intelligence for predictive maintenance and smart adjustments.

- Remote Monitoring: Managers can track machine performance and diagnostics via mobile or desktop apps.

- Plug-and-Play Systems: Faster setup and integration with existing workshop tools.

As the digital skills gap narrows and demand for custom work increases, CNC automation will be essential for growing a competitive CNC workshop in the UK.

Conclusion: Build Smarter with Micromax Group UK

The woodworking industry in 2025 is all about agility, precision, and smart investment. If you’re looking to scale your operations or start your first CNC journey, now is the time to act.

At Micromax Group UK, we specialise in helping small CNC businesses and workshops find the right solution—from choosing a machine to delivery and setup.

Explore our CNC machinery range or contact us for a quote today.

Boost your workshop. Future-proof your business.

Leave a Reply